PPE

Precision Polymer Engineering Critical Sealing Solutions

Semiconductor Products Overview

Some PPE Semiconductor Customers

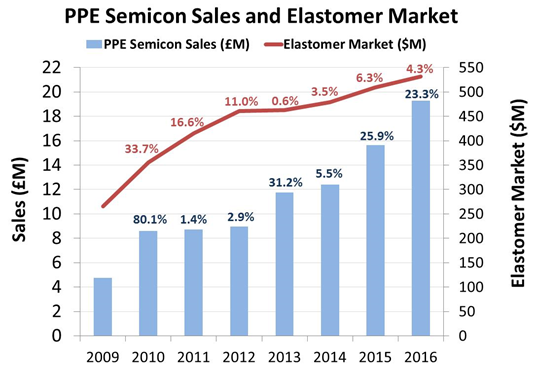

PPE Performance vs. Elastomer Market

Last 4 years, PPE has outperformed the market by 20% to 2300%

PPE SAM is growing faster than total elastomer market

> We identify faster growing process sectors

> We identify the end markets that grow faster

> We focus our resources

> We innovate

Product Overview

High performance O-rings

Diameters from 1mm up to 2.6m

High performance seals and gaskets

X-Seals, lip seals, other geometries

Custom precision moulded parts

End effector pads, microfluidic seals

Bonded elastomers

L-motion, MonoVat SVDs, plastic bonded components

Polymers – FKMs vs FFKMs and PPE Brands

Summary

PPE focus on aggressive applications and critical locations

Vertically integrated – control over total process from design to material compounding to manufacturing

– Unique products gaining market share

Chemical testing/benchmarking gives PPE an excellent platform for recommending correct materials

– Saved time and effort to requalify

– Low risk of incorrect material choice

Perlast and Nanofluor grades are market leaders for low trace metal content

– Minimal risk of electrical yield loss in end device

Expert guidance on hardware matching and Finite Element Analysis

– Correct material and size for application